| Professor

of Heat and Mass Transfer Multi-scale Modeling Lab - SMaLL E-mail: pietro.asinari AT polito.it Mail: Department of Energy, Politecnico di Torino, Corso Duca degli Abruzzi 24, Zip Code 10129, Torino, Italy Phone: +39 011 090 4434 Fax: +39 011 090 4490  Artificial Compressibility Method HOMISBOLTZ code EnerGRID Cluster Facility |

Kyoto, 2012 Last updateDecember 23rd, 2016 |

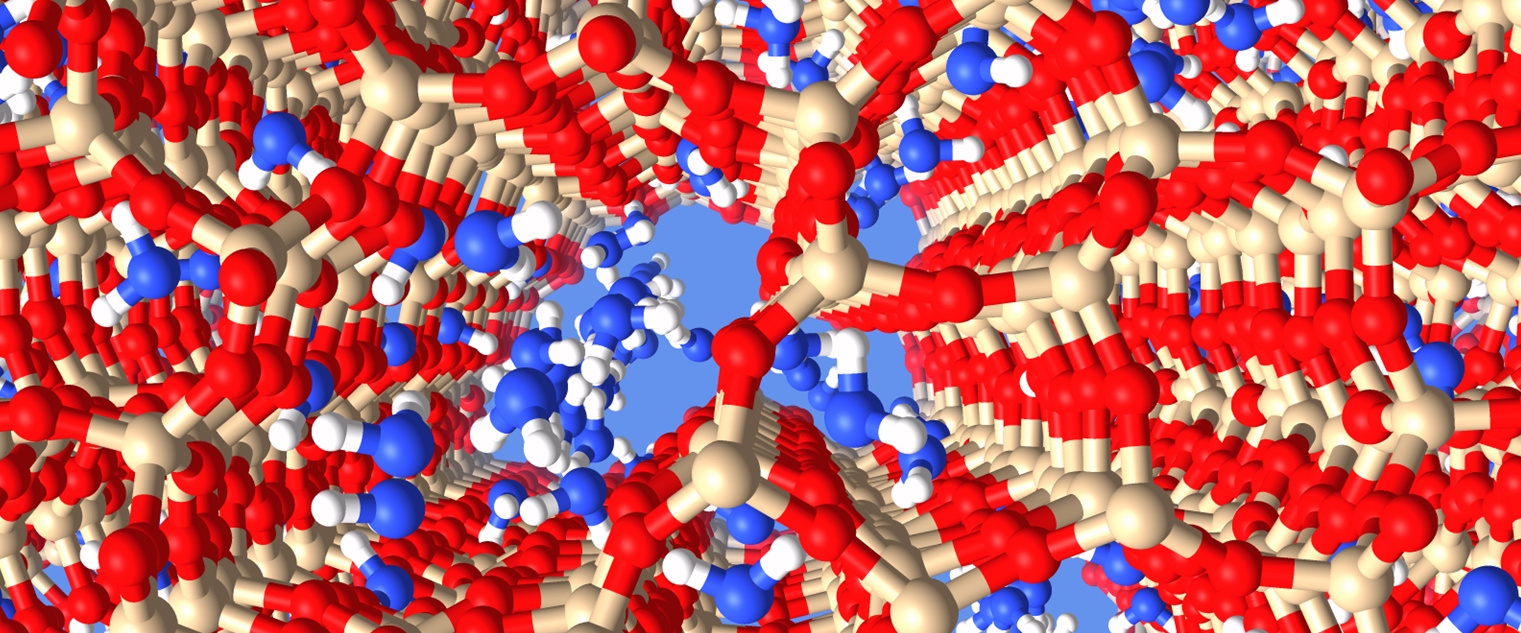

A comprehensive understanding

of molecular transport within nanoporous materials remains

elusive in a broad variety of engineering and biomedical applications.

In the

recent paper published by Matteo Fasano, Elio Chiavazzo and Pietro

Asinari on NATURE

Communications in collaboration with the Massachusetts

Institute of Technology (MIT), experiments and

atomistic simulations are synergically used to elucidate the

non-trivial interplay between

nanopore hydrophilicity and surface barriers on the overall water

transport through zeolite

crystals. At these nanometre-length scales, these results highlight the

dominating effect of

surface imperfections with reduced permeability on the overall water

transport. A simple

diffusion resistance model is shown to be sufficient to capture the

effects of both

intracrystalline and surface diffusion resistances, thus properly

linking simulation to

experimental evidence. This work suggests that future experimental work

should focus on

eliminating/overcoming these surface imperfections, which promise an

order of magnitude

improvement in permeability. More

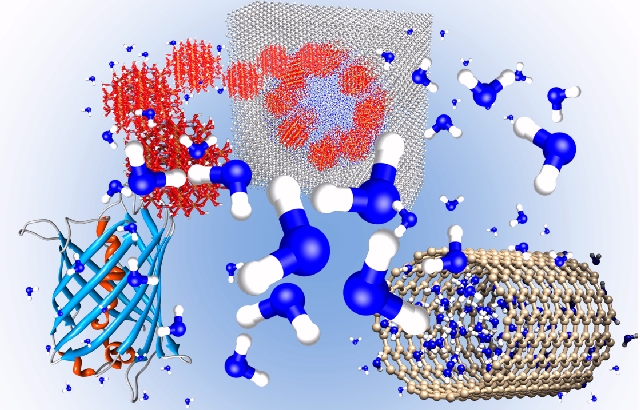

The

transport of

water in

nanoconfined

geometries is different from bulk phase and has

tremendous implications in nanotechnology and biotechnology. In the

recent paper published by Elio Chiavazzo, Matteo Fasano and Pietro

Asinari on NATURE

Communications, the molecular dynamics is

used to compute the self-diffusion coefficient D of water within

nanopores, around

nanoparticles, carbon nanotubes and proteins. For almost 60 different

cases, D is found to

scale linearly with a parameter which represents the ratio between the

confined and total water

volumes. As an example, such relationship is shown to accurately

predict the relaxometric

response of contrast agents for magnetic resonance imaging. This

relationship can help

in interpreting the transport of water molecules under nanoconfined

conditions and tailoring

nanostructures with precise modulation of water mobility. More

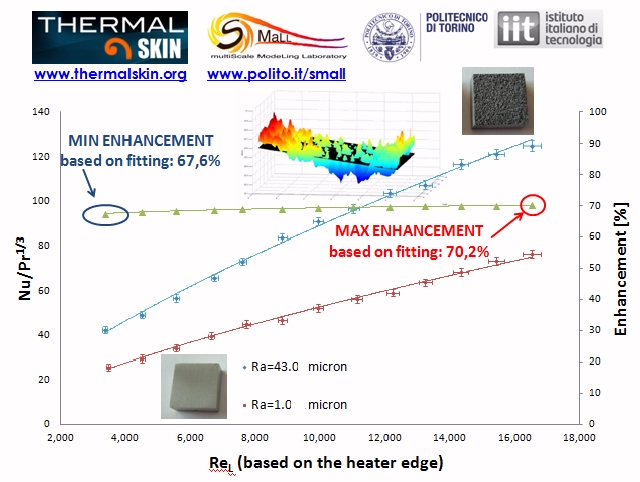

In

the

recent paper published by Luigi Ventola, Eliodoro Chiavazzo and Pietro

Asinari on

Int. J. of Heat and Mass Transfer, experimental evidences are

reported on the potential of direct metal laser sintering

(DMLS) in manufacturing at and finned heat sinks with a remarkably

enhanced convective heat transfer coefficient, taking advantage of

artificial

roughness in fully turbulent regime. To the best of our knowledge, this

is the

first study where artificial roughness by DMLS is investigated in terms

of such

thermal performances. On rough at surfaces, we experience a peak of 73%

for the convective heat transfer enhancement (63% on average) compared

to

smooth surfaces. We propose

that heat transfer close to the wall is dominated by eddies with size

depending

on the roughness dimensions and the viscous (Kolmogorov) length scale. More

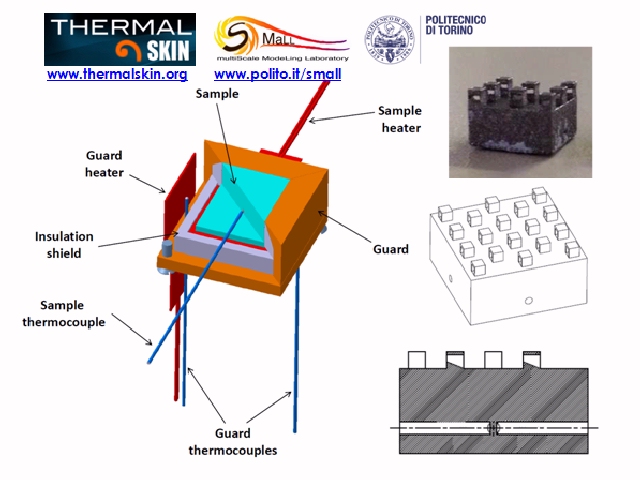

In the recent paper published by Eliodoro Chiavazzo, Luigi Ventola and Pietro Asinari on Experimental Thermal and Fluid Science, a sensor for measuring small convective heat flows (<0.2 W/cm^2) from micro-structured surfaces is designed and tested. This sensor exploits the notion of thermal guard and is purposely designed to deal with metal samples made by additive manufacturing, such as direct metal laser sintering (DMLS). Similar works in the literature often have the necessity of maintaining one-directional heat flows along the main dimension of a conducting bar using insulating materials. Such an approach can be critical for small fluxes due to the curse of heat conduction losses along secondary directions. As a result, it is necessary to estimate those secondary fluxes (e.g. by numerical models), thus making the measurement difficult and indirect. On the other hand, depending on the manufacturing accuracy, the present sensor enables to practically reduce at will those losses, with direct measurement of the heat flux. More

“Genius is one percent inspiration and ninety-nine percent perspiration”, Thomas Edison